IEC Connector Manufacturer

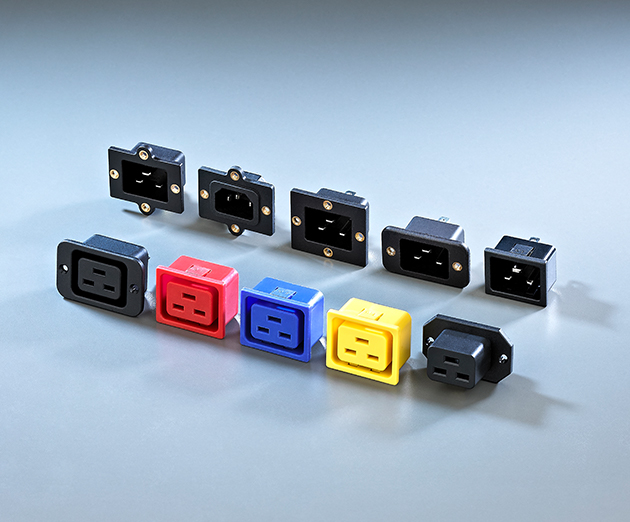

IEC connectors are used to link power to electrical appliances. IEC stands for the standards set by the International Electrotechnical Commission, which ensures that power cords for appliances meet safety requirements for devices with a voltage of up to 250 V ac and a maximum current of 16 A. Lanz Electronic, as an experienced manufacturer of IEC connectors, offers specialized power connection solutions for industrial, commercial, and OEM applications.

-

LZ-14-F18 Hot Sell Ac Power Inlet Connector 250V Ac Socket Plug with Fuse Switch Socket Electrical Plug IEC320 C14 Black

Read moreLZ-14-F18 Hot Sell Ac Power Inlet Connector 250V Ac Socket Plug with Fuse Switch Socket Electrical Plug IEC320 C14 Black

-

LZ-14-F19 AC Power Socket With Double Fuse High Quality Male Female Socket Power Connector Industry Plug

Read moreLZ-14-F19 AC Power Socket With Double Fuse High Quality Male Female Socket Power Connector Industry Plug

-

LZ-14-F1S-4P Safety Ac C14 4pin Power Socket Inlet Plug with Socket IEC Standard Standard Grounding Black 1000pcs 10A/15A CN;ZH

Read moreLZ-14-F1S-4P Safety Ac C14 4pin Power Socket Inlet Plug with Socket IEC Standard Standard Grounding Black 1000pcs 10A/15A CN;ZH

-

LZ-14-F2-3PB Power Socket C14 ac inlet socket with fuse

Read moreLZ-14-F2-3PB Power Socket C14 ac inlet socket with fuse

-

LZ-14-F3W AC Power Socket C14 Type Socket Plug with Female Socket TUV CCC KC CE UL CAS Industrial Standard Grounding 5-40N

Read moreLZ-14-F3W AC Power Socket C14 Type Socket Plug with Female Socket TUV CCC KC CE UL CAS Industrial Standard Grounding 5-40N

-

LZ-14-F4 Ac Power Socket Mount Plug Panel Inlet Sockets with Boat Rocker Switch 220v 4pin AC 500v(50hz)/min Standard Grounding

Read moreLZ-14-F4 Ac Power Socket Mount Plug Panel Inlet Sockets with Boat Rocker Switch 220v 4pin AC 500v(50hz)/min Standard Grounding

-

LZ-14-F8 All copper card type AC power socket socket holder with double fuse case widely use for medical

Read moreLZ-14-F8 All copper card type AC power socket socket holder with double fuse case

-

LZ-14-T1 Assembly Adapter Rewirable Plug C13 C14

Read moreLZ-14-T1 hot selling Wholesale Price 10A/250V Black IEC C14 Male Plug Rewireable Power Connector 3-pin Socket

-

LZ-14-T1R+LZ-14-T2R 10A 250V IEC 320 Server Tech C14 Angled to C13 plug connector

Read moreLZ-14-T1R+LZ-14-T2R 10A 250V IEC 320 Server Tech C14 Angled to C13 plug connector

-

LZ-14-T2R 10A 250V IEC 320 Server Tech C14 Angled to C13 plug connector

Read moreLZ-14-T2R 10A 250V IEC 320 Server Tech C14 Angled to C13 plug connector

-

LZ-16-1 Inlet Connector Plug Power Socket Iec320 C16 10A/250V AC 3 Pin Extension Socket Electric Usage IEC Standard Customer Logo

Read moreLZ-16-1 Inlet Connector Plug Power Socket Iec320 C16 10A/250V AC 3 Pin Extension Socket Electric Usage IEC Standard Customer Logo

Reliable IEC Connectors for Your Business Needs

Common Types of IEC Connectors

An IEC connector is is commonly used to connect power cords to a variety of electrical and electronic devices. The most common types include:

- C1/C2: For small appliances (e.g., electric trimmers).

- C5/C6: Cloverleaf connector, used in projectors.

- C7/C8: Figure-eight connector for stereo systems and laptops.

- C13/C14: For larger appliances (e.g., computers, kitchen devices).

- C15/C16: Kettle lead, used in high-temperature applications.

- C15A/C16A: Higher temperature rating than C15/C16.

- C17/C18: Used in audio equipment for high-quality power.

- C19/C20: For high-current applications (e.g., UPS systems).

- C21/C22: Heavy-duty connectors for industrial and medical use.

- C23/C24: High-power connectors for industrial applications.

Custom IEC Connectors

We understand that every business has unique power connection needs. Our team is dedicated to helping you select the perfect IEC connector for your project. We offer customized solutions tailored to meet your specific requirements, ensuring both optimal performance and safety.

Standardization: Our connectors comply with global safety and interoperability standards, including IEC 60320, ensuring reliable performance across different regions and applications.

Safety: Designed with durability in mind, our connectors incorporate heat-resistant materials, secure earth connections, and appropriate current/voltage ratings to minimize risks and ensure safe operation.

Versatility: We offer both rewireable connectors (for creating custom cables) and non-rewireable (molded) connectors, with additional options like V-Lock cord retention to prevent accidental disconnects.

Whether you need standard or custom IEC connectors, LANZ provides solutions that meet the highest standards of quality and safety.

Custom IEC Connectors

Durability and Performance

IEC connectors are built to strict international standards and made with durable, high-quality materials to ensure secure, stable, and long-lasting electrical connections, even under heavy load or in demanding environments.

Compatibility

Their standardized design allows integration across IT, consumer electronics, medical devices, industrial machinery, data centers, and home appliances, with multiple types supporting various voltage, current, and temperature needs.

Ease and Efficiency

Designed with clear interfaces and intuitive layouts, IEC connectors simplify installation, maintenance, and replacement, while providing reliable performance at competitive costs that help reduce long-term operational expenses.

IEC Connector FAQ

IEC connectors are internationally standardized power couplers defined by the International Electrotechnical Commission (IEC) for connecting power cords to electrical and electronic devices. They follow IEC 60320 standards to ensure safety, compatibility, and interchangeability across products worldwide.

We supply a full range of IEC 60320 types to fit different power requirements, including common types such as C13/C14 for IT and consumer electronics, C19/C20 for high current systems like UPS and PDUs, C5/C6 cloverleaf, and others for specialized applications.

IEC connectors are used in a wide variety of sectors, from IT and data centers, office and household equipment to industrial machinery, medical devices, and more, wherever standardized, safe, and serviceable power connections are needed.

Yes. Because IEC standards are globally accepted and often adopted or referenced by national electrical codes, IEC connectors are suitable for products sold across different regions with consistent safety and compatibility.

Our IEC connectors undergo strict quality control and carry international certifications such as CE, UL, CCC, and TUV, ensuring they meet both performance and regulatory requirements for global markets.

Yes, as a factory-direct manufacturer, we provide custom IEC connector solutions tailored to your specifications. We offer unique mechanical designs, panel footprints, cord retention options, and performance requirements to support your product development.

Lead times depend on the product type, customization level, and order quantity. For standard catalog parts, typical manufacturing lead times range from weeks, while custom orders may require longer. Please contact our sales team for precise schedules.

Key considerations include voltage and current ratings, mating compatibility, temperature requirements, grounding needs, and any environmental or application-specific factors. Choosing the correct type ensures safety and performance.

You can contact us via the quote form on this page, send an email to our sales team, or reach out through other distributor channels. We are happy to provide samples, technical support, and pricing for your evaluation.